The art of roasting

Roasting is a cooking process that transforms a green coffee bean into a roasted coffee bean.

Perle de Café coffee is created in a small coffee-roasting shop using traditional techniques. As a result, the coffee beans from each terroir are roasted in a 22-kg drum roaster. Each has its own unique roast profile.

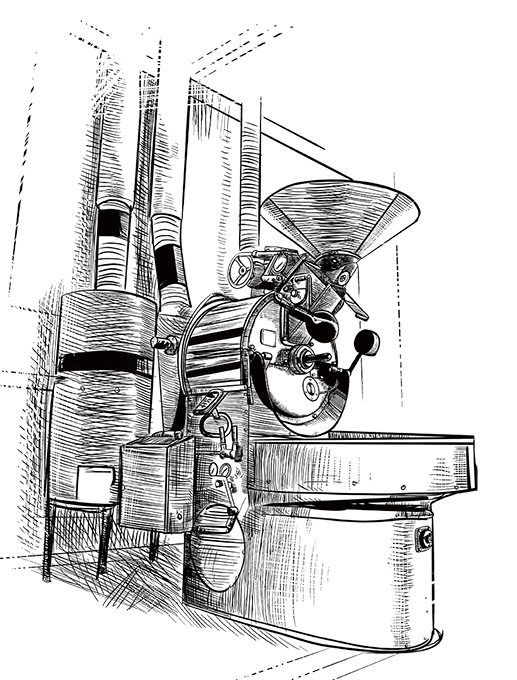

The roaster

We use the PROBAT UG 22 roaster. This roaster, highly appreciated for its performance and reliability, is an indispensable tool for making exceptional coffees.

This gas roaster combines the best of both tradition (quality materials, classic drum architecture) and modernity (roasting monitoring with real-time curves, computerised recipe control, etc.). First designed in 1920, it is still manufactured according to the original plans.

With a capacity of 22 kg, this machine can roast small quantities of beans, delivering consistent quality, in order to enhance the flavours of our coffees.

Cooler

Supplied with fresh air from outside

Three arms stirring the coffee

Stops the roasting process after the beans leave the drum

Loading hopper

Buffer stock of green coffee before roasting.

Air extraction

Evacuates smoke from the drum.

Coupled to the ventilation system, it can be used to control the intensity of the heat in the drum.

Control console

Equipped with a touchscreen, it gathers all the roasting process data in real time.

The master roaster uses this to monitor the roasting process and thus respect the desired roast profile of the coffee.

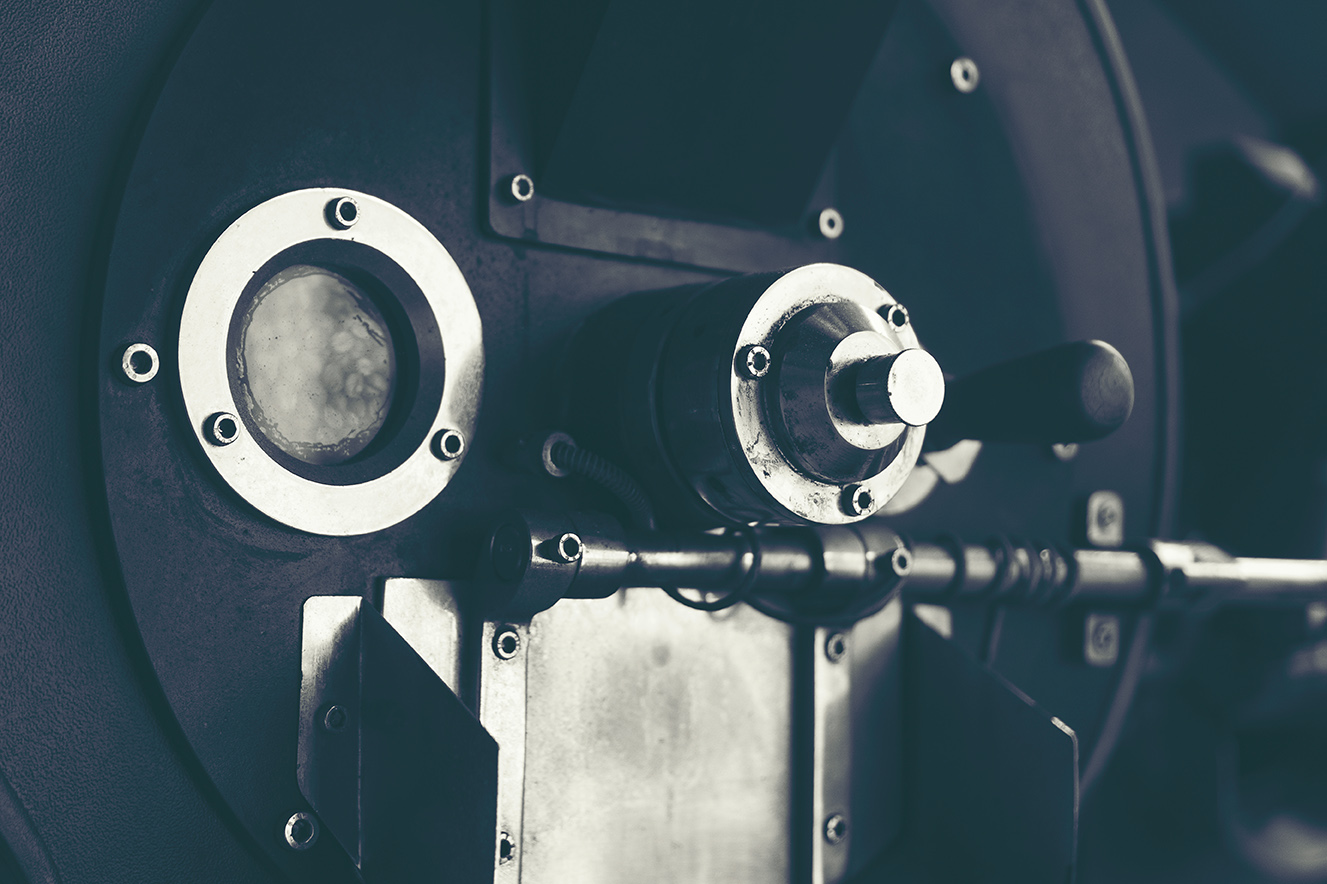

Core drilling machine

Located in the middle of the drum, this enables the roaster to manually sample the coffee.

In this way, the roasting process can be visually monitored.

Drum

The heart of the machine. Heated by the burner, it runs continuously,

stirring the beans and enabling an even diffusion of heat.

Its double-walled structure ensures good heat conduction to the beans, without damaging them.

Temperature sensor

This is positioned to give the most accurate possible reading of the temperature of the beans.

It enables the temperature and the heating rate to be monitored via the control console.

Burner

Located under the drum, this provides the heat necessary for roasting.

Its intensity can be adjusted via the control console.

The stages of roasting

We roast in the traditional way. Our roasting cycles are gentle and slow (10/15 min). This process enables us to bring out the full potential of our speciality coffees.

As each coffee is different (altitude, density, variety, processing, etc.), we adapt the roasting of the beans to each recipe and/or origin in order to achieve the exact roasting objective. In general, roasting can be characterised by 3 successive stages:

The room-temperature beans enter the drum which is heated to +/- 200 °C. The beans will then lose their moisture and absorb the heat transmitted by the roaster. Aroma development is quite mild at this stage.

At the end of the drying process, there is a noticeable change in the colour of the beans. This is known as the yellow point. It is the start of a whole series of chemical and physical reactions in the beans. They will turn brown, start to swell and the flavours will slowly develop.

At the peak of these chemical reactions, the pressure inside the beans increases to such an extent that the beans crack. This marks the start of the development time. The volume of the beans increases by 1.5 to 2%, while they will lose about 17% of their mass. During this phase, up to 800 aromas can develop. The roaster must then stop the roasting process at the right moment to find the perfect balance of body, acidity, bitterness and flavour.

It is essential to monitor and control the roasting process. To do this carefully, we use a highly efficient roast monitoring software called CROPSTER.

This dedicated tool allows us to manage the entire coffee roasting process (from the green coffee beans to tasting the finished product) with great precision, thus guaranteeing consistent coffee quality.

The master roaster

As the guarantor of a long tradition, the master roaster knows the varieties of each coffee perfectly and adapts the roast profile to each origin to bring out its full potential.

He meticulously monitors each of his roasts. Thanks to his experience and with the help of efficient monitoring tools, our roaster will develop each aroma in the coffee beans by following a roast profile specific to each recipe.

Roasting is not just a job. It is a passion.